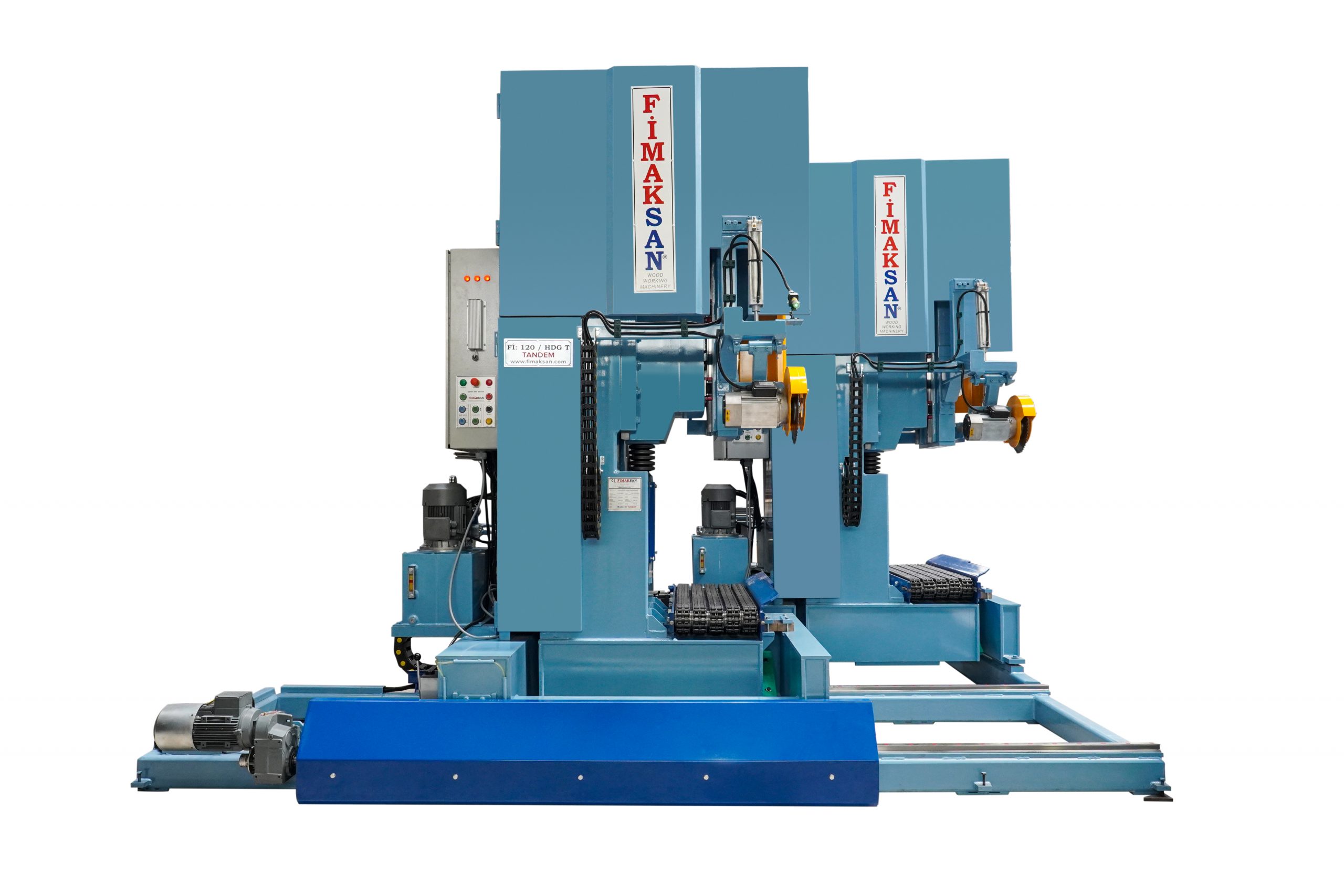

Fİ.120 HİDROLİK – TANDEM ŞERİT

Technical Specifications

✓ Flywheel Diameter | 1200mm

✓ Flywheel Width | 140mm

✓ Max. Log Cutting Height | 1150mm

✓ Max. Cut Width | 640mm

✓ Working Width | 700mm

✓ Cutting Height min | 20mm

✓ Main Motor | 45 kW / 60 hp / 1400 rpm

✓ Sawblade Tensioning | Hydraulic

✓ Sawblade Guide Adjustment | Hydraulic

✓ Upper & Lower Bearings | SKF – C3

✓ Max. Strip Length | 140 X 1.2 X 9300 mm

✓ Min. Strip Length | 140 X 1.2 X 8850 mm

✓ Sawblade Lubrication System | Automatic with Push Button

✓ Lubrication of the Bearings | Manual with a grease pump

✓ Electric Panel (Star-Delta) | Included. First class Material. Mounted

✓ Belt Drive Pulley System | MountedFlender type the pulleys

✓ Body Structure | Steel construction

✓ Movement Tandem System | Linear slides and linear screw system

✓ Positioning Tandem Bandsaw | PLC Control Panel. Colour Touch Screen

✓ Weigth | 10 000 kg. ( Mobile: 5500 kg Fixed: 4500 kg )

✓ Dimensions (L x W x H) | 343 x 185 x 320 cm (Length Width Height)

✓ Dimensions / Moving body (L x W x H) | 163 x 470 x 320 cm (Length Width Height)

özellikler

- Tandem strip (double logging saw) is called the system that emerges with the synchronized operation of two separate strip looms one after the other.

- When the logs loaded on the cutting cart come to tandem saws automatically, two planks / boards are cut in one go due to the 2 band saws adjusted in different sizes. Different cutting sizes can be adjusted at once.

- The first Bandsaw, which is close to the operator, can be position inward or outward. Meanwhile second band saw is in fixed position.

- 60 hp. The flywheel scrapers and the fueling system of the motor-driven strips are made from the operator's cabin with a remote control. The system has been designed according to universal working conditions. Optionally, it has the opportunity to work without tandem.

- Band saw according to the capacity demand of the company; Flywheel Diameter can be produced in different sizes as 100”/120”/140“.

- The strips are suitable and safe for cutting large diameter logs due to their ergonomic design. (saw body distance: 64 cm)

- The daily lumber processing capacity in the carriage + single band system increases by 90% when the ”Tandem" system is preferred. “Tandem band" pays for itself economically in a short time without operating costs, area and additional personnel expenses.

- Daily log processing capacity with the carriage+ single bandsaw system increases by 90% when the “Tandem bandsaw” system is installed and nearly doubles. The “tandem bandsaw” pays for itself economically in a short time, without operating costs, area, and additional worker costs.